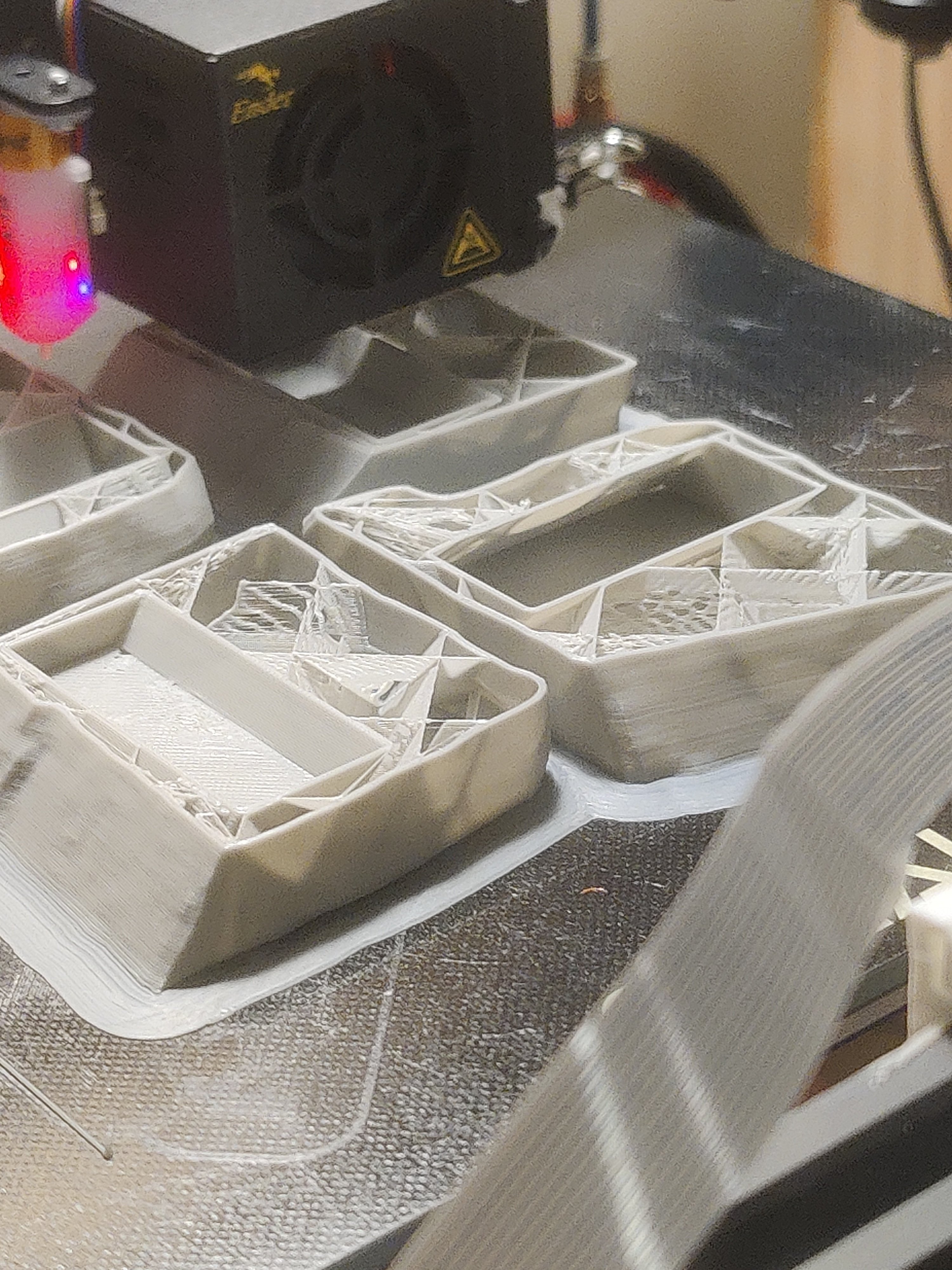

Is your infill move speed just set to be absurdly fast or something?

Also, is it part of the design of your model for the walls of your parts to be all wavy like that?

I’m printing this design , so i think yes they are kind of wavy

Yeah, I definitely think they’re extruding the insides too fast. Perhaps it’s a partial clog, or maybe the settings are too high.

It has been a while, i’ll both unclog and replace the nozzle and see if that fixes anything

Overall this looks like under-extrusion, I’d try a few things:

- Check the flow rate in your slicer. Make sure it didn’t get bumped down by accident.

- Check the filament diameter in the slicer. This getting set wrong can cause all kinds of headaches.

- Slow down the print. The extuder may not be able to push plastic fast enough to keep up with what you are trying to do.

- Raise the tool temperature. The plastic may not be melted enough to flow well.

- Check for a clogged nozzle. Try doing a cold pull to clear the nozzle. Google “cold pull” for good instructions on how to do one.

- Watch for the extruder slipping while printing. If the extruder has worn, it’s teeth may not be engaging the filament well and not pushing it as expected.

- Try different filament. Maybe you have a bad batch and it’s just giving you problems.

- Replace the nozzle. They do wear out and start causing funny problems.

I try to keep most cura settings pretty default, i think everythings as it should be so it may def be hardware or filament related. I really hope it’s not the latter since i’m super on a time crunch right now lol

Do give the settings a once over. I had some really weird printing problems when Cura got set to a 2.8mm filament setting. And I really have no idea how it got changed. Prints got much better when I found and fixed that.

I just tried them on default, problem now is after putting on a fresh new .4 nozzle the extruder can’t even get it through anymore, I even tried manually pushing the filament and it wouldnt budge, Im beginning to think I’m gonna have to disassemble the whole hotend and clean it all

I would argue those walls are not printing fine. They look janky.

You’re probably right. Regardless, one problem at a time, if you fix the glaring one oftentimes the other ones turn out to be symptoms , and I’m on a production crunch so I really can’t spare any extra time getting it just right, perhaps later

I only bring it up because the source of that problem and your infill issue may be related.

No you have a point, i definitely need to see if I can improve that once I’m done with this project. I’m getting some slick upgraded parts soon which may help

Have you calibrated it well? Have you done the slicer setting calibrations?

Are you using pressure advanced?

No I’ve heard of linear advanced, but never pressure

I think they are the same thing. One is klipper terminology.

Sorry if this is a bad picture, currently have a big gash on my camera lens

I think infill is just moving too quickly for the output of filament. You could try messing with the temperature to make it flow better, but since the outside looks okay, I would probably just try slowing down infill speeds, if it were me. Hope you get it sorted!

New Lemmy Post: My outer walls are printing fine, but my infills are super wispy (https://lemmy.world/post/9805382)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md